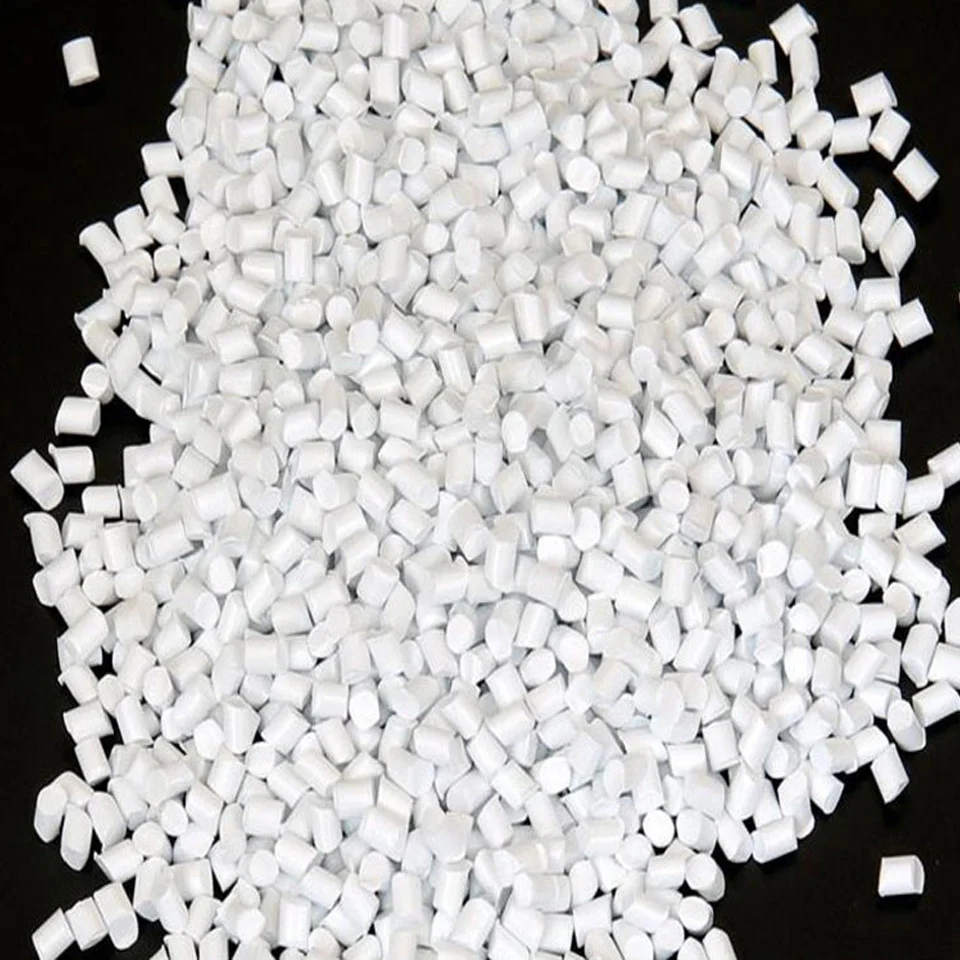

Black Masterbatches

Black masterbatch is a concentrated mixture of carbon black (pigment), carrier resin (polymer), and functional additives. It is the most common method for coloring plastics black because it is cleaner, easier to handle, and more cost-effective than using raw pigment powders.

Beyond color, it acts as a high-performance additive that protects plastics from environmental degradation.

Composition & Core Components

A typical black masterbatch consists of three primary elements:

- Carbon Black (15% – 50%): The pigment that provides “jetness” (depth of black) and opacity.

- Carrier Resin: A polymer (like PE, PP, PS, or EVA) that must be compatible with the base plastic being colored.

- Additives: These can include antioxidants, processing aids, or UV stabilizers to improve the final product’s performance.

Key Benefits

- UV Protection: Carbon black is one of the most effective light stabilizers, absorbing harmful UV rays that would otherwise cause plastic to become brittle or yellow.

- Mechanical Strength: High-quality masterbatches can actually reinforce the polymer, improving tensile strength and impact resistance.

- Dispersion: Advanced manufacturing ensures the carbon particles are spread uniformly, preventing “streaks” or clumps in the final product.

- Conductivity: Specialized grades can be used to make plastics antistatic or electrically conductive for electronics packaging.

Common Applications

| Industry | Typical Use Case |

| Packaging | Garbage bags, industrial stretch wraps, food containers. |

| Agriculture | Mulch films (to suppress weeds), irrigation pipes, and greenhouse covers. |

| Automotive | Bumpers, dashboards, interior trims, and under-the-hood components. |

| Construction | HDPE water pipes, geomembranes, and wire/cable insulation. |

| Consumer Goods | Home appliances (washing machines, blenders), electronics, and toys. |

Technical Selection Criteria

When choosing a black masterbatch, manufacturers look at:

- Jetness: How deep and rich the black appears (measured by “tinting strength”).

- Particle Size: Smaller particles (20-30\text{ nm}) generally offer better UV protection and deeper color than larger particles (60-70\text{ nm}).

- Melt Flow Index (MFI): This determines how easily the masterbatch flows during the manufacturing process (injection molding vs. extrusion).