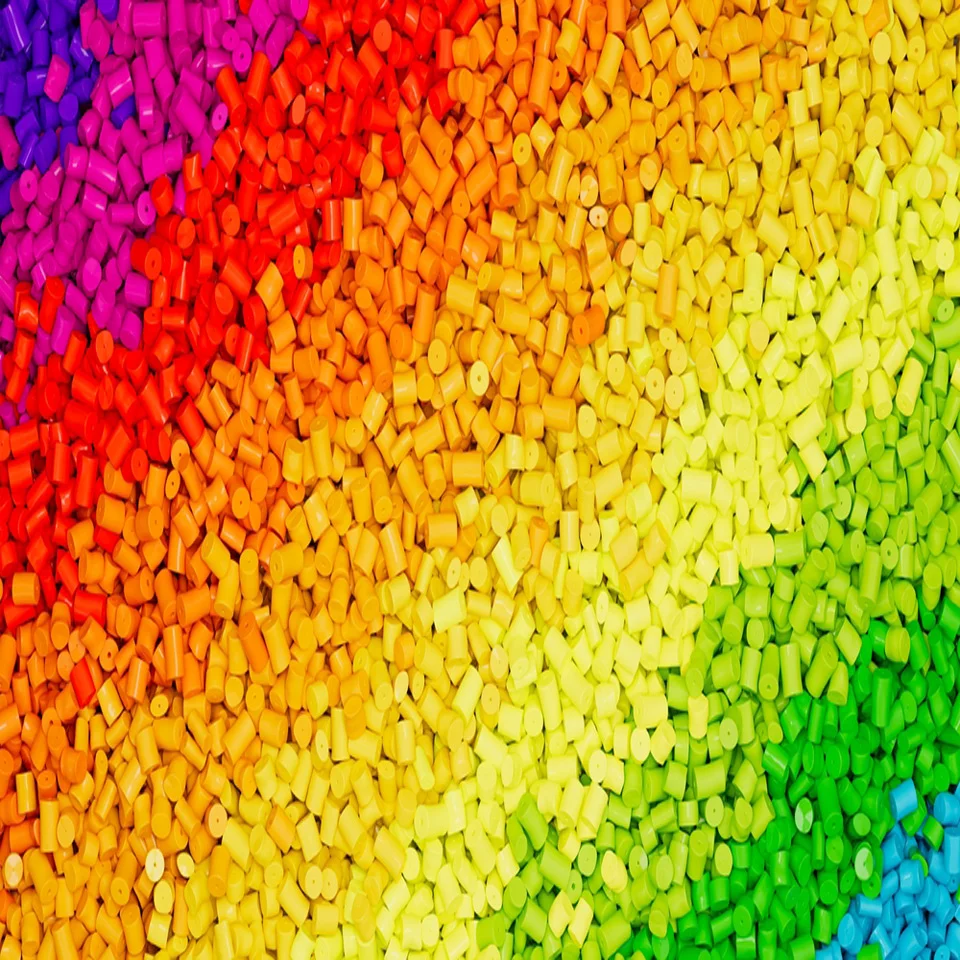

Color Masterbatches

Color masterbatches are concentrated mixtures of pigments and additives encapsulated during a heat process into a carrier resin, which is then cooled and cut into a granular shape. They are the most efficient way to add color to plastic products during manufacturing.

Composition and Production

A masterbatch is essentially a “delivery system” for color. It consists of four primary components:

- Pigments/Dyes: Organic or inorganic colorants (e.g., Titanium Dioxide for white, Carbon Black for black).

- Carrier Resin: A polymer (PE, PP, PS, etc.) that must be compatible with the plastic being colored to ensure seamless melting.

- Dispersants: Agents like polyethylene wax that help pigments spread evenly without clumping.

- Additives: Optional ingredients for extra functionality, such as UV stabilizers or flame retardants.

The Manufacturing Process

- Mixing: Raw materials are blended at high speeds to pre-disperse the pigments.

- Extrusion: The mixture is fed into a twin-screw extruder where it is melted and homogenized.

- Pelletizing: The molten plastic is extruded through a die, cooled in a water bath, and cut into uniform pellets.

Types of Color Masterbatches

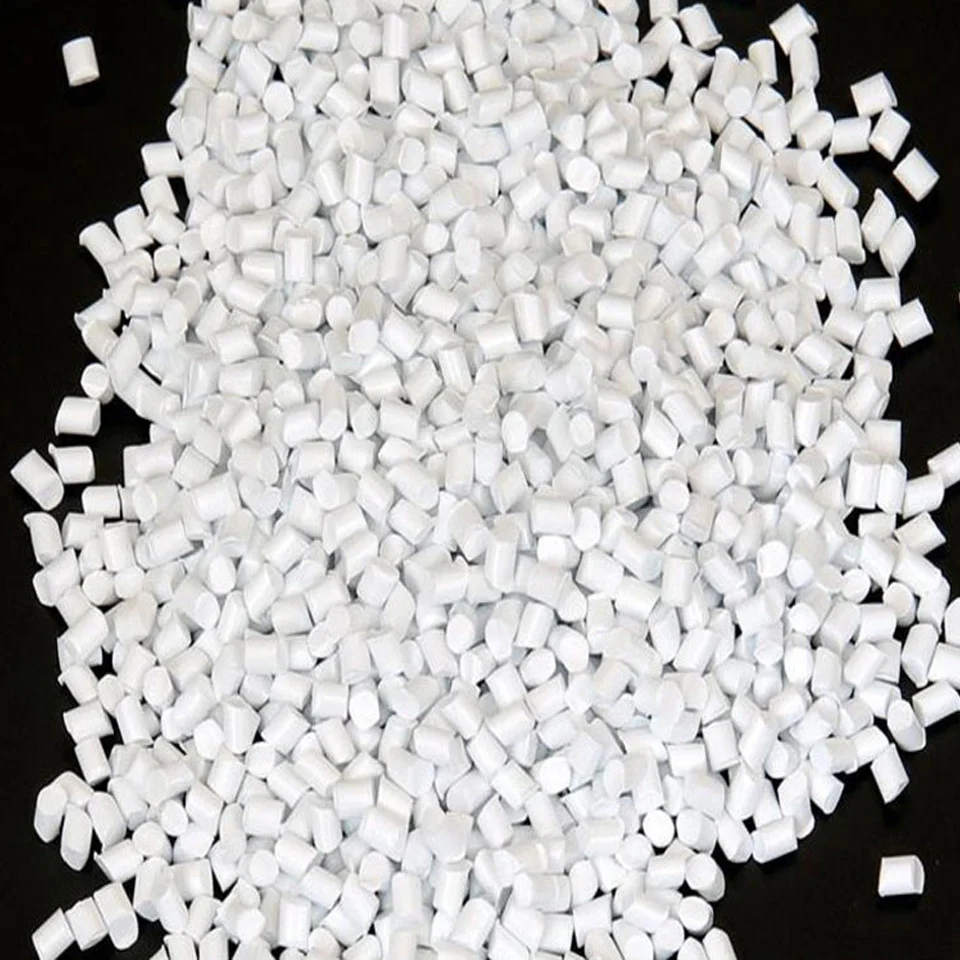

| Type | Characteristics | Common Uses |

| White | High concentration of TiO_2 (up to 80%). Provides opacity and brightness. | Milk bottles, food packaging, lamination. |

| Black | Uses Carbon Black. Provides UV protection and conductivity. | Irrigation pipes, geomembranes, automotive parts. |

| Color | Thousands of custom shades (Red, Blue, Green, etc.). | Toys, household appliances, furniture. |

| Special Effect | Includes pearlescent, metallic, fluorescent, or marble effects. | Cosmetic packaging, luxury goods, high-end electronics. |

Key Advantages in Production

Using masterbatches is often preferred over raw powders or liquid dyes for several reasons:

- Cleaner Handling: Eliminates airborne dust and pigment contamination in the factory.

- Dosing Precision: Pellets are easy to weigh and meter into the “let-down” (dilution) process, typically at a ratio of 1% to 5%.

- Consistency: Pre-dispersed pigments ensure a uniform shade across millions of units, preventing streaks or “spots.”

- Stability: The carrier resin protects pigments from moisture and oxidation during storage.

Market Leaders (2025–2026)

As of early 2026, the industry is heavily focused on circularity and PFAS-free solutions. Major players include:

- Avient Corporation: A leader in medical-grade and sustainable colorants.

- Ampacet: Known for design-led special effects and TiO_2-free options.

- Cabot Corporation: Specializes in “REPLASBLAK” circular black masterbatches for automotive use.

- Clariant: Recently completed a shift to a fully PFAS-free additive portfolio.

- LyondellBasell: Provides high-volume solutions for the packaging and construction industries.