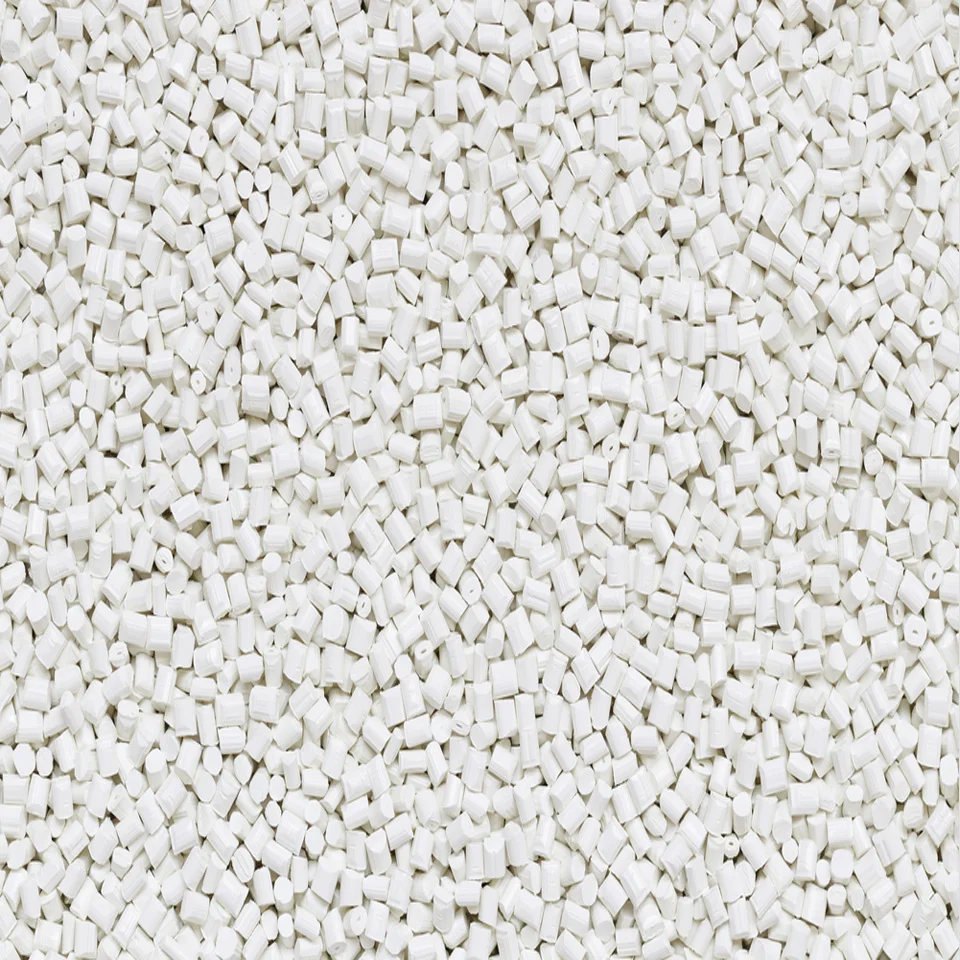

White Masterbatches

White Masterbatch is a concentrated mixture of pigments—primarily Titanium Dioxide (TiO_2)—and a carrier resin. It is the most widely used type of color masterbatch in the plastics industry, used to provide whiteness, brightness, and opacity to finished products.

1. Composition and Key Ingredients

The quality of a white masterbatch is largely determined by its loading and the type of pigment used:

- Pigment (TiO_2): Usually ranges from 20% to 75% of the total weight.

- Rutile Grade: Offers high refractive index, superior opacity, and excellent UV resistance. Best for outdoor applications.

- Anatase Grade: Known for being “bluer” and brighter but has lower weather resistance. Often used for indoor products.

- Carrier Resin: Must be compatible with the base plastic (e.g., PE, PP, PS, or ABS).

- Additives: May include processing aids, UV stabilizers, and antioxidants to prevent yellowing or degradation during manufacturing.

2. Common Applications

White masterbatches are essential in almost every sector of plastic manufacturing:

| Industry | Typical Products |

| Packaging | Food containers, milk pouches, shopping bags, and cosmetic tubes. |

| Agriculture | Greenhouse films, mulch films, and irrigation pipes. |

| Consumer Goods | Household appliances (fridges, toasters), toys, and furniture. |

| Medical | Syringes, IV bags, and specialized medical tubing. |

| Construction | PVC window profiles, siding, and drainage pipes. |

3. Technical Benefits

Using a masterbatch instead of raw pigment powder offers several industrial advantages:

- Superior Dispersion: Ensures a smooth, uniform color without streaks or “specks” of pigment.

- UV Protection: TiO_2 naturally acts as a UV shield, preventing the plastic from becoming brittle or yellowing under sunlight.

- Opacity: Effectively masks the natural color of the base resin, even in very thin films.

- Cleanliness: Eliminates the dust and contamination issues associated with handling raw powder pigments in a factory setting.

4. Key Considerations for Selection

When choosing a white masterbatch, manufacturers look at:

- Melt Flow Index (MFI): Should match or be slightly higher than the base resin to ensure easy mixing.

- Heat Stability: Must withstand the high temperatures of extrusion or injection molding (often up to 280°C).

- Food Contact Compliance: For packaging, it must meet FDA or REACH standards.

Note: For high-end “thin film” applications (like 10-micron bags), a high-quality masterbatch with extremely fine particle size is required to prevent “pinholes” or tearing during production.