In the plastics industry, color masterbatch is a concentrated mixture of pigments and/or additives encapsulated during a heat process into a carrier resin, which is then cooled and cut into a granular shape.

Essentially, it is a “color concentrate” that allows manufacturers to color raw polymer (plastic) efficiently and cleanly during the molding or extrusion process.

Think of raw plastic resin as water and masterbatch as highly concentrated fruit squash. You only need a small amount (typically 1% to 5%) to change the color of the entire batch.

The Mix: Small pellets of masterbatch are mixed with “natural” (uncolored) plastic pellets.

The Melt: Both are fed into a machine (like an injection molder or extruder).

The Result: The heat melts the carrier resin, releasing the pigments and dispersing them evenly throughout the plastic to create a uniform final color.

Using masterbatch is generally preferred over using raw powder pigments for several reasons:

Cleaner Production: Powders create dust that can contaminate the factory and pose health risks. Masterbatch is dust-free.

Better Dispersion: Pigments are already “pre-dispersed” in the carrier resin, which prevents streaks or spots in the final product.

Dosing Accuracy: It is much easier to weigh and measure solid pellets than fine powders or liquid dyes.

Storage Efficiency: Manufacturers can buy large quantities of cheap “natural” resin and keep a small stock of different masterbatches to create any color they need on demand.

While “Color” is the most common, there are several specialized types:

| Type | Purpose | Common Uses |

| :— | :— | :— |

| White | High opacity and brightness (using $TiO_2$). | Food packaging, medical devices. |

| Black | Deep black color and UV protection. | Agricultural films, pipes, cables. |

| Special Effect | Aesthetics like metallic, pearlescent, or “glow-in-the-dark.” | Cosmetics, toys, luxury packaging. |

| Additive | Adds functional properties (Anti-static, UV stabilizer, Flame retardant). | Outdoor furniture, electronics. |

Formulation: Determining the exact ratio of pigments, additives, and carrier resin.

Mixing: Raw ingredients are combined in a high-speed mixer.

Extrusion: The mixture is melted and pushed through a twin-screw extruder to ensure the pigments are perfectly distributed.

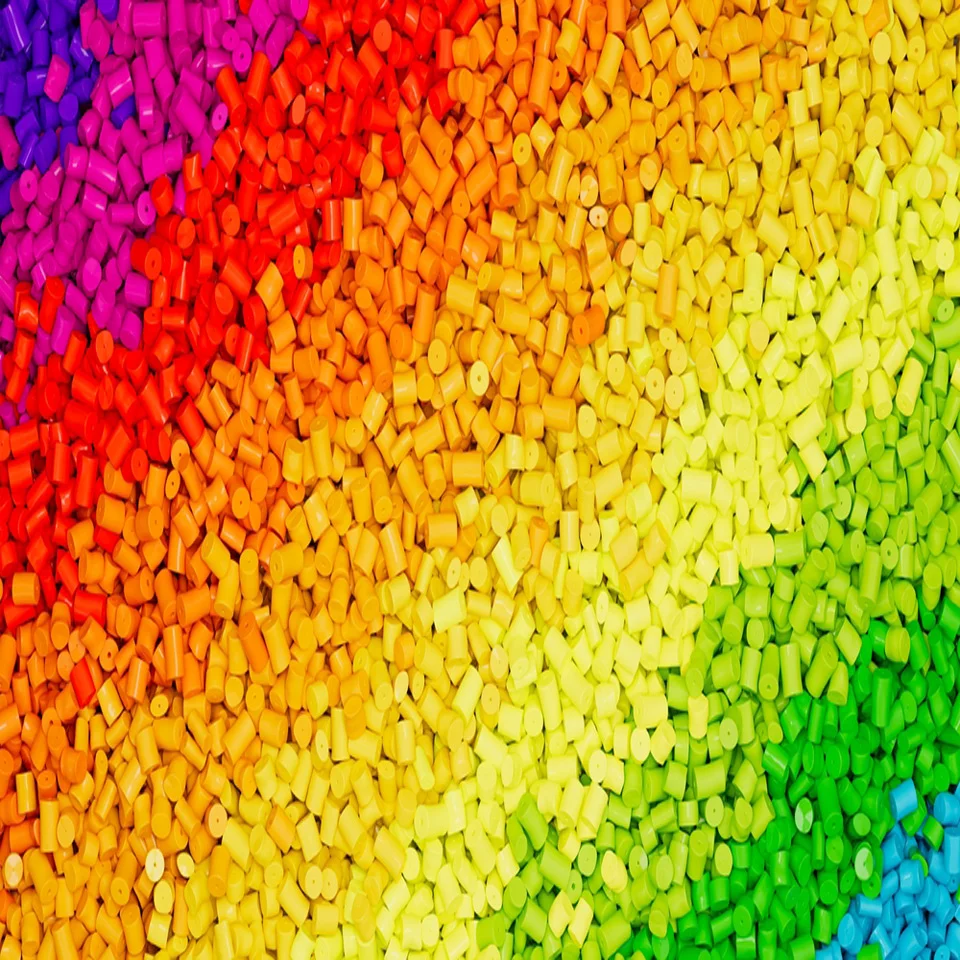

Pelletizing: The molten plastic “strands” are cooled in water and chopped into the final pellets you see in the industry.

Masterbatch: You mix it yourself. It’s cheaper and offers more flexibility with inventory.

Pre-colored Resin: The plastic arrives already colored. It is easier to use but more expensive and requires storing large volumes of specific colors.

We founded in 2010 producing Masterbatch (MB) based on PE, PP , PS , ABS , PC , TPU , EVA , PMMA with wide ranges of colors degrees, we have different types of additives and filler Masterbatch.

© 2026 Created with Mohammed Zida